Brushless Motors -

Brushless and brush slot car motors depend on the same basic principles. Both

have electric currents that needs to be reversed at the right time so the coils of

wire rotate relative to permanent magnets. The key differences are:-

- In brushless the magnets rotate and the coils of wire don't : With conventional brushed motors the coils of wire rotate and the magnets don't

- In brushless the current in the coils of wire is reversed by an electronic commutator (ecom) board : Bushed motors have brushes and a commutator to reverse the current in the coils

How is it wired?

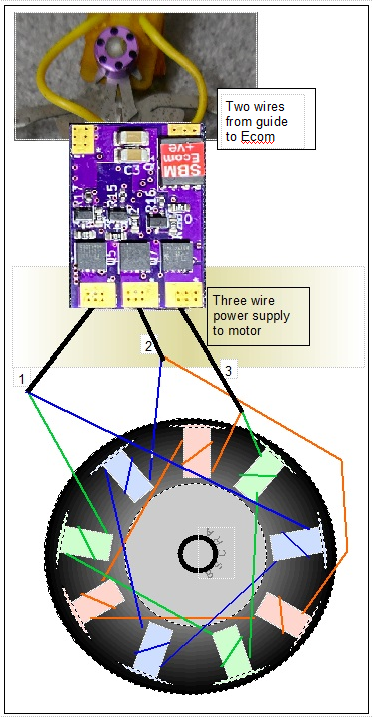

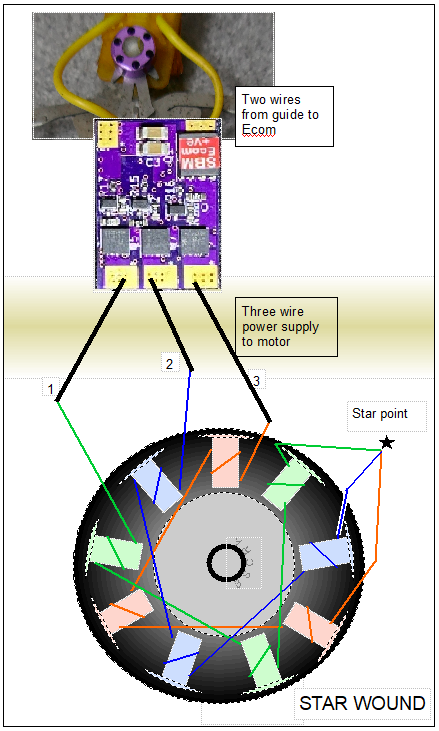

At first sight it seems a bit complicated, but let’s have a go at explaining what’s going on in the diagram.

Firstly a normal guide picks up dc power from the two track braids and two wires take dc into the car just as in conventional slot cars.

The Ecom takes the dc and switches it between 3 connections -

The 3 wires to the motor feed power to the brushless motor’s 9 poles. Obviously each pole cannot be fed individually from just 3 wires. It works by feeding power to groups of 3 poles. The 3 poles shown in blue are connected in series between wires 1 and 2 : The 3 poles shown in pink/red are connected in series between wires 2 and 3 : The 3 poles shown in green are connected in series between wires 3 and 1. What’s the result of all that compared with a 3 pole brushed motor (other things being equal)? This brushless motor rotates through a smaller angle each time the current is reversed but produces more torque because it has more poles attracting and repelling the magnets.

© Copyright British Slot Car Racing Association 2021 updated 2023, 2025 Photos copyright C.Frost All rights reserved

Efficiency

Brushless motors have been common in radio controlled model cars for years. Generally

brushless motors convert more of the electrical power into mechanical power at the

wheels so produce less waste heat. That efficiency is a big advantage if your electrical

energy is stored onboard -

There’s

normally plenty of electrical power to spare on a slot car track, so assuming you

can get rid of the waste heat the motor’s efficiency is much less important . However

brushless motors don’t have a commutator to retrue or brushes to wear out.

Cost

A conventional slot car motor is replaced by two parts – the brushless motor itself and the e comm to drive it. A brushless motor without the e comm is as useless as a conventional motor with no commutator or brushes. The brushless motors used in drones are cheap and readily available, major investment is necessary for the quantity production of the specialised e comm electronics needed to make them work. The somewhat different ESCs used in radio control are relatively cheap. The relatively small quantities likely to be produced for slot cars will make slot racing e comms more expensive.

It also possible that standard drone motors will be a starting point for the development of brushless motors specifically for slot racing. If that happens it’s likely specially developed for slot racing motors will be more expensive than standard drone motors.

How does it drive?

Ross Grogan, James Cleave and Will Stemman tried some of Bob and Richard’s brushless cars in September 2021 on the Nationals/ 2019 World Championship track.

Ross and Will found a perceptible delay between coming off brakes and onto power when entering corners. Bob hadn’t found that delay and commented that perhaps Ross and Will are exceptional drivers. Changes to the ESC code have been made to reduce the delay in coming back on power after braking. .

Ross was taking some high speed sections of the track on part throttle with brushless that would be taken at full power with a conventional Eurosport. James commented on the torque didn’t seem to drop at high speed unlike a conventional car where there’s a considerable reduction in torque at higher speed.

Later Developments

This article was originally written in 2021 with some updates in 2023. What’s changed since?

2023 -

In Britain, Martin Ellis won the 2023 1/24 British Open Championship using brushless motors.

2024 -

The brushless motors in the Euosport and Sports classes in both scales were almost

all 1105 or 1106 size with Kv ratings up to around 22000. These powerful motors

are unsuitable for the 1/32 F1 class. Shorter / lower torque motors are widely used

in F1, mostly 1103 size brushless motors. Other developments include user programmable

Ecoms and Ecoms with “auto brakes”

An increasing number of chassis designed for brushless cars came on the market. This meant fewer competitors needed to adapt chassis designed for bushed motors.

An increasing number of brushless motors with the shaft out the right end for slot racing cars came on the market. This meant fewer competitors needed to reshaft motors which were made with the shaft out the right end for drones.

Limited motor classes

At National and International level the limited motor classes continue to use brushed

motors, for example the ISRA 1/24 Production class which uses hand out motors : The

Group 12 motors used in BSCRA’s 1/32 Saloon, 1/24 Production and 1/24 Open Group

12 classes : The FK-

BSCRA members voted for the introduction of brushless motors for the INTRO 32 class in 2026.

A number of clubs and raceways are running classes for brushless powered production

chassis.

Chris Frost

Electronics

Brushless motors have been used in radio controlled racing for years, and there have been slot car experiments using off the shelf radio control electronics in the car and full power on the track all the time. The key difference in Bob Budge’s cars is they are driven with a normal slot car controller which gets away from all the issues of having power on the track braids all the time. The clever bit that makes that happen is the Electronic Commutator (Ecom) These were developed from the electronic speed control (ESC) used in radio control. I’ve been told the first slot racing ESC/Ecom were developed for drag racing in the USA, apparently the development and introduction dates back to 2014.

The boards Bob and Richard are using were developed by Peter Smitt, a Canadian who specialises in designing ESCs mainly for drones. Bob contacted him some time ago and they are working together to develop a reliable and useable design. At the 1/32 Nationals in August 2021 there were only 3 of these SBM Ecoms in existence.

Pete has designed a new, smaller version which is being tested and they are working

on the initial bugs that crop up as testing continues on the old design.

When everything

is finalised the details will be open source and available for anyone to build. Initially

Bob and Richard made a few prototypes but didn’t offer any for sale. Their first

batch for sale quickly sold out in mid 2022. A second batch sold out in December

2022 and more batches in 2023. The 320 SBM Ecoms produced by February 2023 have

been hand made by Richard or Bob so production is slow and demand is far more than

they can cope with, they are looking into ways to produce more. In 2022 the shortage

of components was limiting the number that can be made.

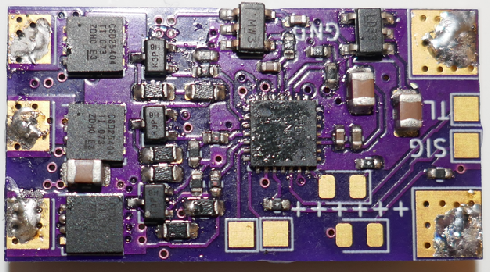

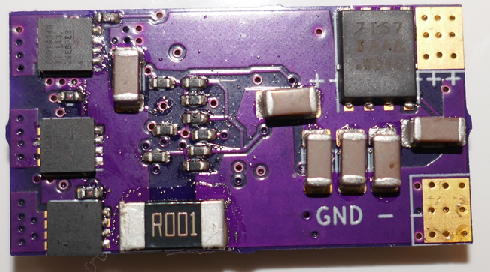

Here are photos of the top and bottom of one of the boards Bob used at the 2021 Nationals. The boards used a the Nats have components mounted top and bottom and are about 29 x 15mm and weighs about 2.8gm. In 2022 a smaller Ecom was produced, about 22.5 x 15mm and weighing about 2gm, the processor runs at 49mHz which allows the motor to run at up to around 110,000rpm. The production batches supplied from mid 2022 allows the motor to run at up to around 150,000rpm.

The Ecom’s processor only runs when it has a high enough voltage, a key part of the development was getting them to work down to a low voltage. The processor shuts down on a SBM Ecoms when the voltage is below about 1¾ volts which happens when the track power is turned off and the motor has slowed down so the back emf is below that voltage. The adjustable brakes on most conventional slot car controllers work with ecoms just like any other slot car, however some problems have been reported with pulsed (PWM) brakes. Testing early versions of ecom in September 2021, when the driver came off the brakes there was 100 millisecond delay before the motor started producing any power. This was perceptible to some drivers. The code was changed to overcome that.

The SBM Ecoms have reverse polarity protection built in so will not be damaged if the car drops into a lane backwards or a power supply is hooked up backwards while testing. Some other makes of ESC / Ecom will fail if reverse polarity power is connected.

I’ve described the SBM Ecom. There are other Ecoms made by Stefano Mirabelli and

NSR in Italy, WestRock in New Zealand, DoSlot and x89 in Germany, Remora in the UK

and Synapse in Brazil. Essentially they all do the same job. I’ve tested 3 of

these makes. Once there has been more comparative testing it’ll be interesting to

hear how the different makes compare. There is an issue with PWM controllers -

Motors

DELTA WOUND

There are two different ways of winding the motor -

Off the shelf motors may be either and the makers often don’t tell you which they

use.

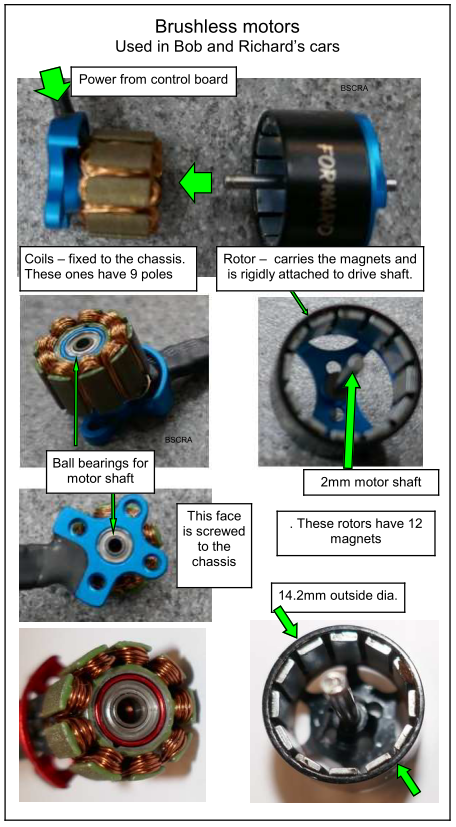

Let’s concentrate on the inner workings of the outrunner 1100 size brushless motors Bob Budge and Richard Mack are using in their slot cars. Thanks to Bob and Richard for all the help with this article Richard credits Stefano Mirabelli with the recommendation for that size of motor. They come in different lengths, Bob and Richard concentrate on the 1106 size, the fourth number is the length of the stator stack (so 1106 has a 6mm long stack, 1103 has a 3mm long stack etc.) shorter stacks give less torque.

These motors have two parts as shown in the illustration. The rotor carries the magnets, this rotates round the outside of the coils and they don’t have sensors. Outrunners come in many different sizes, Bob and Richard have chosen this size many makes have a 14.2mm outside diameter although a few makes are a little smaller. The bare motor weighs 7.2 gm. Complete with pinion and wiring to the connector they weigh 8.1gm. This size motor normally has 2mm or 1.5mm bearings. For the 2mm bore pinions normally used, ones with 2mm bearings is more convenient rather than sleeving a 1.5mm shaft. A shaft protruding out the right end to take a pinion has to fitted, the standard drone motors come with the shaft extending out the wrong end. Richard tells me that’s not a difficult job. In 2023 motors with the shaft already out the right end for slot racing became available.

We are used to feeling the magnetic attraction when turning over a motor, a conventional slot car motor will stop in one of 6 positions, this type of brushless motor will stop in one of 36 positions.

In 2023 there have been experiments with different motor configurations which may allow higher motor speeds with the same Ecoms.

Outrunners aren’t the only type of brushless motor, another common type is the inrunner where the magnets rotate inside of the coils. Inrunners have been tried but Richard tells me they weren't successful.

To do the same job as a conventional slot car motor you need both the brushless motor and the electronics to drive it. The electronics are doing something similar to what the brush gear and commutator do in a conventional slot car motor.

If you’d like more detail, see Richard Lang’s data and calculations.