Official Rule Interpretations

J Bars on JK C43 chassis

Following reports of a loophole in the rules for the 1/24 production chassis being exploited, rule H2.2.14 has been clarified to read

"On the JK C43 chassis 0.8 to 1.2mm diameter unmodified JK " J bars" must be used to join the chassis parts by passing through the holes intended for that purpose."

October 2022 further clarified 2 November 2022

Controller Power Interpretation (becasue of brushless motors)

At present there are very few brushless cars built for BSCRA open classes. Therefore

the practical way to race them is alongside conventional cars rather than in a separate

race for one or two cars. The BSCRA council agreed a rule clarification to minimize

issues with both types on car racing side by side. -

“The motor power must be

directly controlled by a speed controller plugged into lane's controller connector.

Controllers that apply full power to the track all the time are not permitted. “

The

brushless cars already raced at the Nationals comply with this interpretation.

November 2021

Driver Grading Rules Interpreted because of COVID Lockdown

BSCRA driver grading rules have been clarified because of cancelled racing during the covid lockdowns. The rules about how many years drivers stay in a grade will be interpreted to mean the number of years when the racing took place.

Neither the 1/32 Nationals (3 open classes) nor the 1/24 Internats took place in 2020

Therefore under the 5 year rule (Nats rule 2.2 i) 2016 overall National champions will be premier grade for the 2022 season: 2017 National champions will be premier grade for the 2022 and 2023 seasons etc.

Therefore under the 2 year rule (Nats rule 2.2 ii) 2019 overall Nationals finalists will be premier grade for the 2022 season

Therefore under the 10 year rule (Nats rule 2.3 vi) main grade drivers who had a Nats result that qualified them for main grade in 2011 will not be eligible for clubman i the 2022 season etc.

(All the 2019 main grade champions are premier grade for other reasons so no interpretation of Nats rule 2.2 iii is needed)

Neither 1/32 nor the 1/24 BOC took place in 2020 or 2021

Therefore under the 2 year rule (Nats rule 2.2 iii) the 2018 BOC top 5 will be premier grade for the 2022 season : the 2019 BOC top 5 will be premier grade for the 2022 and 2023 seasons

September 2021

Eligibility of DTM Bodyshells for BSCRA Saloon Classes

In 2021 the full size DTM (Deutsche Tourenwagen Masters) has become a series for GT cars instead of the saloon based DTM cars that have been raced up to the end of the 2020 season. Bodyshells of DTM cars have been eligible for both 1/32 and 1/24 scale BSCRA saloon classes. There is no change in the eligibility for bodyshells of the saloon based cars raced in the full size DTM up to the end of 2020 (including the 2 Aston Martin Vantage DTM shells already approved). However, the cars raced in the full size DTM from the start of the 2021 season will not be eligible for the BSCRA saloon classes.

The BSCRA bodyshell policy has been updated.

February 2021

Valiko group 12 armatures

There have been some problems with the original couple of batches of Valiko X12 armatures.

Valiko have recognised their mistake and have produced a 3rd batch of group 12 armatures, and these have been checked by USRA and found to meet the group 12 specification, so (according to BSCRA rules) these automatically become eligible for BSCRA racing.

The original two batches from the Worlds in Finland and UK19 will no longer be eligible for BSCRA organised racing.

January 2021

Extended Bodyshell Eligiability

Due to the coronavirus lock down, stocks of bodies that would have been used this year can be expected to last longer. It has been agreed to allow an extra year to use up bodyshells where eligibility is due to expire at the end of 2020.

The shells concerned that will now be eligible till the end of 2021 are:-

32 Saloon

Betta Opel Vectra DTM and MG Ex259 BTCC

32 Sports

AAA Ferrari 360 Modena and Riley and Scott Mk.IIIC

Betta Riley and Scott Olds' Mk3

JK

Dallara LMP

May 2020

Two Colour Body Rule

BSCRA has been asked to clarify the rule which says “The body must be painted in at least 2 different colours”.

In all the classes where "The body must be painted in at least 2 different colours" is a requirement the following applies

Two colours refers to two different colours applied to different areas of the shell. It doesn’t include one colour applied beneath another, as in fluorescents etc. It is also not sufficient to have ink pen lines, numbers, drivers, front wheels or other detailing required by the rules.

NOTE this applies to Car Standards C3, D1.4, E1.3, F1.3, G3 & H1.2 -

September 2018

Use of the National Championship Track

BSCRA has been asked to clarify the permitted use of the Nationals track in BSCRA Competition rule 22

The "National Finals" means the Finals for 1/32 open class cars (Saloon, F1, and

Sports) In 2018 this event was held on 5-

Before the end of the 2018 season, the BSCRA Council will decide if changes to this rule will be needed for 2019 when some or all of the 2019 events may be run on the track being built for the 2019 ISRA World Championships.

June 2018

C Can Motors

BSCRA has been asked to clarify the requirement for Group 12 motors

Shortening of 'C' can motors is not one of the "Permitted Motor Modifications" in the BSCRA rules. Therefore, shortening of 'C' can motors by any means is not permitted in the “restricted motor” classes. (Motors are of course free choice in 1/32 F1, 1/32 sports and 1/24 Eurosport) The moulded flange register on the endbell must engage with the full length can at the full length end.

Brush Hoods may be modified to allow clearance for springs and shunts to have improved travel.

Clarification will be added to the BSCRA Handbook

March 2017

Armature Tags

BSCRA has been asked to clarify the requirement for armature tags, the BSCRA council has agreed the following

In classes where Group 12 or Super Wasp armatures are required, the scrutineers need to check the armature is eligible by reading the tag, If the tag is missing or impossible to read the arm will fail scrutineering.

March 2017

Motor Approval Policy -

BSCRA has decided it would be useful to clarify the motor policy. This clarification summarizes what the Association (under both the BSCRA and ECRA name) has done in the past so is not a change to existing practice.

Inline with this, the Cahoza motor cans currently approved for BSCRA 1/24 open group 12 racing will continue to be eligible for this class. ( USRA approval of these products has been withdrawn for price reasons.)

The wording added to the BSCRA Motor Approval Policy is-

"When BSCRA approved products are no longer manufactured, they will normally continue to be eligible for BSCRA racing. Normally racers wouldn't want scrap their existing motors just because new ones are no longer made.

Where USRA withdraws approval for a product it previously approved, BSCRA will investigate the reasons. Generally if USRA approval has been withdrawn for distribution or price reasons, BSCRA is likely to allow its continued use. If however USRA have found technical infringements, particularly performance related ones, BSCRA may well decide to withdraw approval for BSCRA racing."

March 2017

Rule clarification for INTRO 32

We have been asked to make it clear if soldering the axle bushings in the Genesis chassis is permitted. The BSCRA Council has decided by a majority vote that soldering will be permitted, so the Intro 32 Assembly rule 9 now reads.

9. The axle bushes may be soldered or bonded in place

November 2015

Rule clarification for BSCRA 1/32 Saloon, Super Production and 1/24 Open Group 12 classes

During the rule change submission process, the CRC have reviewed the permissible modifications to G12 and Super Wasp motors in the various classes. Having looked at some of the ambiguities in the rules and what has become common practice, the CRC have decided to issue the following clarifications about permissible motor modifications in each class..

The motor shaft diameter may be reduced at the drive end of the motor in the 1/32 Saloon, Super Production and 1/24 Open Group 12 classes

(NOTE this allows the use of small bore pinions in these classes)

August 2015

Rule clarification for BSCRA 1/32 Production classes

Soldering of the original can end bearing is allowed on Falcon 7 motors.

(NOTE this was introduced as some members have experienced the bearing coming loose.)

July 2014

Rule clarification for BSCRA 1/24 Production, 1/32 Production and 1/32 Super Production

classes

(Rules E2 and H2)

This clarification explains the BSCRA's interpretation of the following rules:

H2.1 Only the following metal chassis of one material are permitted:

E2.1 The following chassis only may be used:

E2.3.5 Nothing is allowed to be added to the chassis in front of the forward most part of the motor unless otherwise stated in section E.2.2.

It is not permitted to undertake post manufacture heat and/or chemical treatments and/or shot peening to Production chassis components (Centre sections or Pan sections).

Note 1: For the avoidance of doubt this means any such treatment by any person other than by the original manufacturer in the original manufacturing process. Thus it is not permitted for entrants or intermediate suppliers to treat these components, whether by chemical dipping, replating, heat treatment, or addition of any substances including in solid, liquid or gaseous form or any combination of the above.

Note 2: This does not prevent the use of normal soldering or gluing operations on the chassis components to the limited extent specifically permitted in the regulations. Nor does it prevent straightening of bent components.

Note 3: Production car chassis are not eligible under the BSCRA regulations even if the treatments described above are undertaken by the original manufacturer beyond the specification of the approved product.

BSCRA

August 2011

The exiting rule interpretation "The manufacturing processes of some chassis mean that some parts are delivered with quite sharp edges. It is permissible to deburr these edges. This must not result in excessive material removal and any such edge radius must not exceed 25% of the sheet material thickness" apples to BSCRA 1/24 Production, 1/32 Production and 1/32 Super Production classes

BSCRA

August 2011

The above decisions were taken by the BSCRA Council on the advice of the BSCRA Competition Rules Committee

Copyright © 2011, 2014 , 2015, 2017, 2018, 2020, 2021, 2022 British Slot Car Racing Association All rights reserved

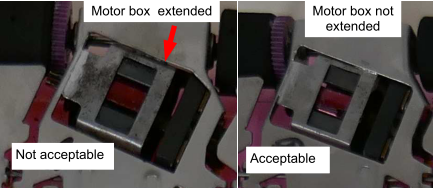

Motor Box on X32 in 1/32 Super Production Chassis

Competitors using the JK X32 chassis are reminded that rule E2.3.7 says “ The front and rear edges of the motor hole may be chamfered to match the side profile of the motor can/endbell as long as the bottom edge of the hole is not extended forward or backwards.” (See page 18 of the Handbook).

The examples in the photos clarify what is acceptable.

December 2022