|

JK Hawk Retro Used example stripped by Chris Frost in September 2021 |

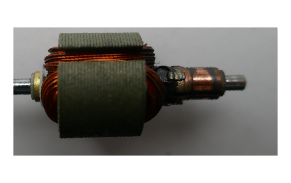

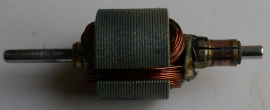

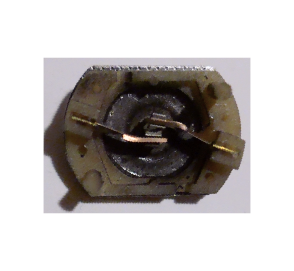

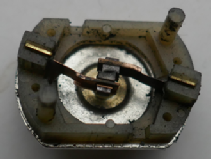

JK Hawk 7 Used example stripped by Chris Frost in December 2021 The motor had gone slow in use. On test it was taking over twice the normal current when free running on 4 volts |

JK Hawk 7 Used example stripped by Chris Frost in January 2022 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Appears to be made on identical tooling to the JK Hawk 7 |

Appears to be made on identical tooling to the JK Hawk 7 stripped in 2013, However it had a row of 7s etched on the can |

Appears to be made on identical tooling to the JK Hawk 7 stripped in 2013, Like the one stripped in December 2021 it had a row of 7s etched on the can |

|

|

|

|

|

Stack dia 13.04mm |

Stack dia 13.07mm Many other examples of the Hawk 7 do have metal removed from the stack indicationg they have been balanced.

|

Stack dia 13.07mm Windings tied at comm end, potting penetrates windings at the comm end which retains them better than the earlier sealed motors, but the rest of the windings are unrestrained (like the other motors) |

|

Wire dia 0.26mm with insulation Dia 0.0091 to 0.0092 inches (approx 0.231- Turns 65 (1 pole counted) |

Wire dia 0.29mm with insulation Dia 0.0092 to 0.0093 inches (approx 0.233- Turns 59 (all 3 poles counted) |

Wire dia 0.29mm with insulation Dia 0.0093 inches (approx 0.236mm) without insulation Turns 59 (2 poles counted) |

|

|

|

|

|

|

Com not tied |

Tied com |

|

Different batches have different shaft lengths. Some tension is needed when unwinding the outer layers of wire at comm end due to the potting of the tied at comm. This will tend to keep the windings in place which should help with reliability. |

No evidence of the com having been tied. There was no evidence of any potting, just as in the 2013 example the windings could simply be un wound with hardly any tension This motor had 59 turns. |

This motor had 59 turns. |

Hawk Falcon 7 and Approximate Equivalents 2021/22

This is the most recent strip downs of Hawk type motors. See page 2 for earlier strip

downs of approximate equivalents -

Motors

V

© Copyright British Slot Car Racing Association 2021 -